QUALITY - COMPLIANCE - INTEGRITY

DUNTY METAL is committed to establish, communicate, implement, review, monitor, measure, and continually improve the effectiveness of the Quality Management System that assures material and services, procured and supplied by DUNTY METAL conform to customer, regulatory, and statutory requirements.

During the production process of titanium, multiple processes of testing and quality control are required to ensure that the quality of the product meets the requirements. Commonly used detection methods include chemical composition analysis, metallographic structure observation, mechanical property testing, etc. Only through strict quality control can the quality of titanium products be guaranteed to be stable and reliable.

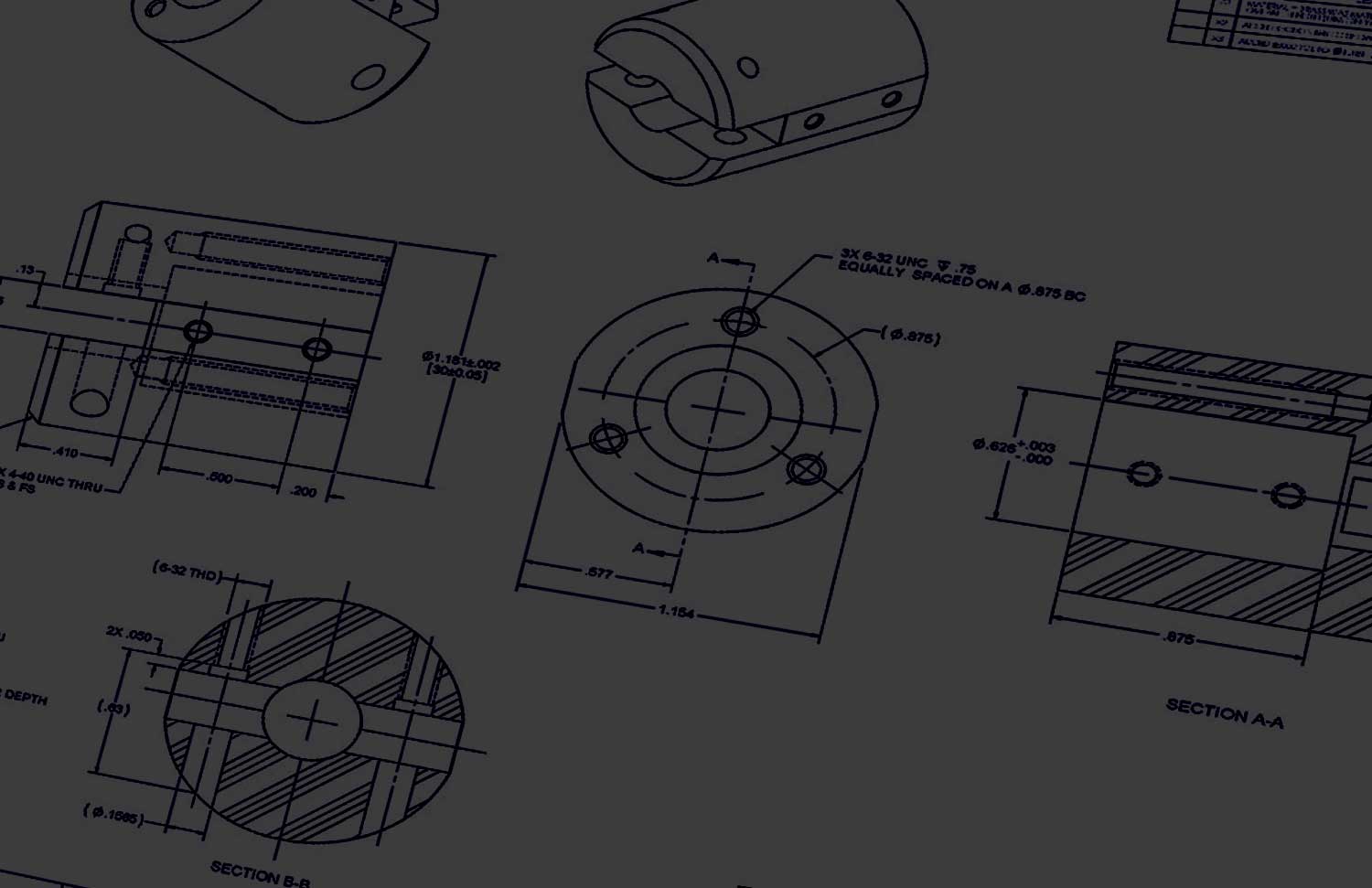

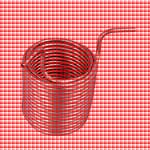

Find out moreProcess Of Titanium Pipes Production

All process we stand for you

1

Smelting

Selected sponge titanium is smelted to ensure the quality of raw materials.

2

Tube blank

The titanium alloy block is heated to the appropriate temperature and then formed into a tube blank by forging, extrusion or rolling.

3

Heat treatment

In order to improve the mechanical properties and corrosion resistance of titanium tubes, the tube blanks need to be heat treated.

4

Titanium tube forming

The tube blank is shaped to obtain the desired pipe shape and size. Methods mainly include cold drawing, hot extrusion and spinning, etc.

5

Annealing

In order to eliminate stress and improve the grain structure, the titanium tube needs to be annealed. After annealing, the mechanical properties and corrosion resistance of the titanium tube will be further improved.

6